Stop Check Valves

Filter

Stop Check Valves combine the mechanisms of Globe Valves and Check Valves to provide efficient flow isolation as well as reliable backflow prevention. Stop check valves combine the automatic backflow prevention operations of check valves with the manual shut off capabilities of globe valves, hence the “stop” name. Some are even able to manually regulate flow regardless of the forward or backward flow rates.

Stop check valves are essentially globe valves with floating discs and stems that are not as rigidly connected to the disc. Since the disc moves automatically based on system pressure, the check function can operate automatically and independently from any manual throttling adjustments. These valves default to an open position where the disc allows flow to move freely and smoothly, but it will close securely back onto its seat if backflow is detected. However, unlike other types of check valves, stop check valves also have a handwheel actuator that can be manually operated. So, when the handwheel turns, the stem can push the disc down fully for tightly sealed shutoffs, and in some cases, it can push the disc down partially for precise flow control. These valves can be installed in horizontal upward or downward flow and in vertical upward flow.

This dual-function capability makes stop check valves a popular choice in industrial systems that benefit from a combined globe and check valve functionality in one unit. They can effectively prevent damage to equipment like pumps and boilers through the protective layer that is provided with reliable backflow prevention. This makes stop check valves particularly beneficial to boiler systems in high-pressure steam, high-temperature steam, or general steam services. Applications that use boiler systems include heat recovery steam, steam generation, utilities, power plants, turbine cooling, shutdown cooling, geothermal services, and more.

Cooney Brothers is proud to supply our customers with a wide range of stop check valves from Crane Stop Check Valves to Spears Stop Check Valves.

We also carry two popular lines of Crane Stop Check Valves that are commonly used in many industries: Crane 28E Straight Stop Check Valves and Crane 30E Angle Stop Check Valves.

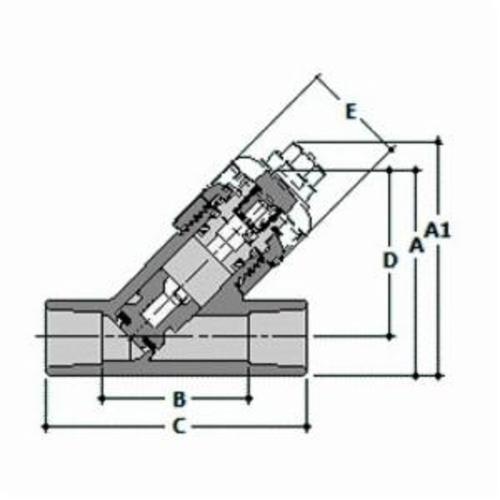

With different materials, trims, and configurations available, we carry valves anywhere from ½” - 10” in size and they all have a 250 pressure class. Our selection of body material ranges from CPVC Stop Check Valves to PVC Stop Check Valves to Ductile Iron Stop Check Valves. Our supply of stop check valves have either straight or angle flow paths in both T-pattern and Y pattern designs. Y-Check Valves are more ideal for applications that require minimal pressure loss since they have lower full-open flow velocities than the traditional T design. We also offer a variety of end styles including FNPT, Special Reinforced FNPT, Flanged, and Socket. Most of our stock uses bolted bonnets, but some come with welded or pressure sealed bonnets for specific application needs.

Contact us for industry expertise on your specific need and check out our selection of dependable stop check valves.

CBPN:

11921

MPN:

30E-3

CBPN:

125318

MPN:

30E-5

CBPN:

260234

MPN:

1622-005

CBPN:

11924

MPN:

30E-6

CBPN:

11922

MPN:

30E-4

CBPN:

79613

MPN:

30E-2-1/2

CBPN:

159425

MPN:

30E-10

CBPN:

13423

MPN:

30E-8

CBPN:

11921

MPN:

30E-3

CBPN:

125318

MPN:

30E-5

CBPN:

260234

MPN:

1622-005

CBPN:

11924

MPN:

30E-6

CBPN:

11922

MPN:

30E-4

CBPN:

32353

MPN:

28E-3

CBPN:

1683

MPN:

28E-6

CBPN:

79613

MPN:

30E-2-1/2

CBPN:

159424

MPN:

28E-10

CBPN:

24313

MPN:

28E-2-1/2

CBPN:

25226

MPN:

28E-4

CBPN:

24312

MPN:

28E-5

CBPN:

32348

MPN:

28E-8

CBPN:

159425

MPN:

30E-10

CBPN:

13423

MPN:

30E-8