Swing Check Valves vs Lift Check Valves vs Stop Check Valves

Differentiating Between Check Valve Types for the Best “Fitting” Application

While there are many types of Check Valves, Swing Check Valves, Lift Check Valves, and Stop Check Valves are the three most commonly used and well-known check valves across all industries.

In order to pick the right check valve for your specific residential, commercial, or industrial application, you must first be familiar with the check valve types and how they differ. Except for their shared backflow prevention function, each type has its own unique capabilities, design, and features.

No check valve type is superior to the others. They simply operate differently and are intended to be used in different applications/working conditions.

Let’s define Swing, Lift, and Stop Check Valves to give you a fuller picture of how each type works:

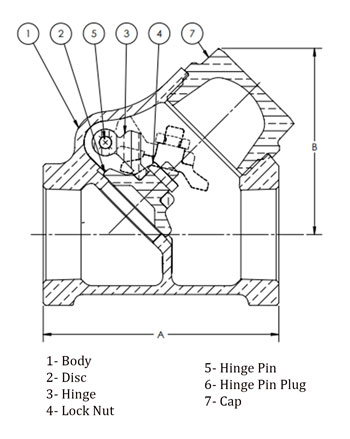

What are Swing Check Valves?

The Swing Check Valve gets its name from its swinging hinge mechanism that operates automatically to prevent backflow when closed and allows for a full, unidirectional flow when opened. There are two different types of swing check valves:

Top-Hinged Swing Check Valves: This type is typically the standard for swing check valves as it is the most common of the two by far. Pressure from the flow forces the hinged disc to “swing” open and then swing back onto its seat when the pressure drops.

Tilting Disc Swing Check Valves: This type uses a dome-shaped, floating disc that allows fluid to flow above it or below it by tilting into an open position and closing quickly when backflow is detected. The disc is spring-loaded so the valve can close off flow faster than a top-hinged valve.

Swing check valves can also be manufactured in angled-flow designs that are referred to as “Y-Pattern” or in the traditional straight-through flow design. This straight-flow form is often not given a specific label since it is considered standard, but it can be referred to as “T-Pattern”. Either way, swing check valves are primarily installed in horizontal lines, but they can be installed vertically as long as the flow always moves upward. Since swing check valves allow for almost fully uninterrupted fluid pressure when open, they have low amounts of pressure drop.

Swing is generally the most widely recognized check valve type, which could be for a variety of reasons. On top of effective backflow prevention and unobstructed flow capabilities, these swing check valves are also the lowest in cost. These capabilities make swing check valves perfect for low pressure systems where backflow needs to be prevented, especially for safety reasons. They can also be specially designed for high temperature operations when manufactured with the right materials. However, a downside is that they are most susceptible to disc oscillating or slamming from pressure/flow surges. This means that, unless they are specially designed, they tend to not perform well in systems with high pressure, high velocity flow, or flow conditions that often change or pulsate. These valves could experience premature wear and therefore, shorter service lives but only when used in harsh working or flow conditions.

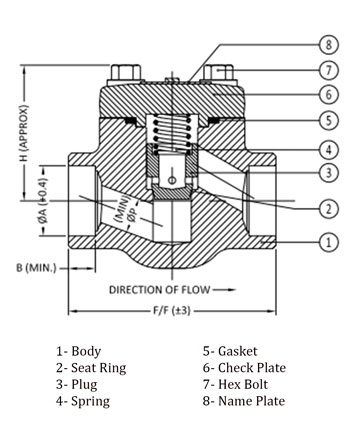

What are Lift Check Valves?

The Lift Check Valve is coined from the “lift” motion it uses for allowing full open/close capabilities in one direction as well as automatic backflow prevention. A piston or ball disc lifts or drops based on the pressure of flow. When flow enters, the pressure raises the disc into a lifted, open flow position, but when flow stops or reverses, gravity and the drop of pressure forces the disc to drop back onto its seat for a full shut off.

Whether you’re working with Piston Lift Check Valves or Ball Lift Check Valves, lift check valves are usually manufactured in the traditional horizontal body pattern but vertical and angle lift check valves are also available. Lift check valves are typically installed horizontally but they do allow for a vertical installation as long as the disc can still easily move up and down. Lift check valves have a narrower flow path than swing check valves, so their pressure drop is higher than that of a swing check valve.

Despite their higher pressure drop and cost, lift check valves have their own advantages. They are generally less expensive than lift check valves but more than swing check valves. They work particularly well in applications with extreme working conditions like both high pressure and high temperature operations. Even with a slightly more restricted flow path, lift check valves can handle the conditions of high-velocity flow and changing/pulsating flow better than swing check valves. They also work well with applications that need to maintain a certain level of pressure because the disc mechanism identifies any drop in pressure and counteracts it with a complete and quick shut off. They are also less susceptible to oscillating or slamming, offering a longer service life with minimal wear and less maintenance needs than the swing check and lift check.

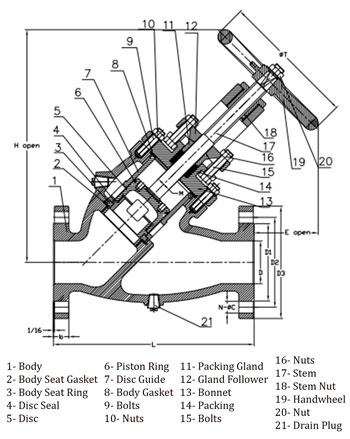

What are Stop Check Valves?

The Stop Check Valve is named after its combined backflow prevention and manual “stop” or “regulate” flow capabilities. They allow flow to move in one direction, and they combine the flow isolation and regulation of globe valves with the automatic backflow prevention of check valves. Their internal disc automatically moves based off of system pressure levels and works similarly to lift check valves in how it floats freely and drops once backflow is detected. But this disc can also be manually controlled by a handwheel actuator that, when turned, can push the disc up for a full open, down partially for a regulated flow, or down completely for a full shut-off.

Like swing and lift check valves, there are two designs that stop check valves often use:

T-Pattern Stop Check Valves: This design is generally the standard as it offers a straight flow path with minimal turbulence and friction. This means that this design offers less susceptibility to wear over time as well as lower pressure loss and a smoother, more efficient flow.

Y-Pattern Stop Check Valves: In this design, the stem and disc are angled at 30 to 45 degrees, allowing for a lower full-open velocity. They come in straightway or angled flow paths. While angled design is advantageous in certain applications like on top of boilers, they have to be monitored more than T-Pattern Stop Check Valves because they are more susceptible to wear from flow turbulence and pressure loss.

Stop check valves can generally be installed horizontally or vertically, but horizontal installation is preferred because it simplifies the operation of the disc by taking gravity out of the equation. Straightway stop check valve designs should be installed in horizontal or vertical lines with upward flow, and angled stop check designs should be used in upward-to-horizontal or horizontal-to-downward flow. Like lift check valves, their flow paths are slightly more restricted than that of swing check valves. However, their pressure drop still tends to be lower than with lift check valves, especially in the Y-pattern, straight-way designs.

Stop check valves are often the most expensive check valve type since their manual actuation requires more moving parts, making them bulkier and more costly to make. However, they prove to be a popular choice in systems that benefit from the versatility of having precise flow control and backflow prevention in one unit. With a mid-range level of pressure loss, stop check valves also have versatile capabilities, working well in high-pressure, low-pressure, high temperature, and high velocity operations. They are commonly found in safety and shut down services where quick flow isolation is important for maintenance or emergencies. But they are not advantageous for pulsating or frequently changing flow because any repeated opening and closing of this valve could lead to disc oscillating or slamming. This combined with their higher maintenance needs creates a moderate level of wear overtime and therefore, a middle-of-the-road service life.

Quite a bit of information to keep track of right? See the table below for a quicker, easier way to compare globe valves vs gate valves and for even more contrasting characteristics:

Differentiating Between the Check Valve Types

|

|

Swing Check Valves | Lift Check Valves | Stop Check Valves |

|---|---|---|---|

| Function | Full open flow service with automatic backflow prevention | Full open flow service with automatic backflow prevention | Manual full open, closed, and regulate flow services with automatic backflow prevention |

| Disc Mechanism | Swinging top-hinged or tilting disc controlled automatically by pressure levels | Piston or ball disc controlled automatically by pressure levels | Free floating disc controlled automatically by pressure levels and manually by actuator |

| Body Design | T-Pattern, straight-through flow design (standard) or Y-Pattern, angled-flow design | Straight-through (standard) or angled flow designs | T-Pattern, straight-through flow designs (standard) or Y-Pattern, angled-flow designs |

| Flow Direction | Unidirectional | Unidirectional | Unidirectional |

| Flow Efficiency | Completely unobstructed flow | Unobstructed flow with some resistance from narrow flow path | Unobstructed flow with some resistance from narrow flow path |

| Install Configuration | Mainly installed horizontally but can be installed vertically with upward flow | Mainly installed horizontally but can be installed vertically with upward flow | Mainly installed horizontally but can be installed vertically with upward flow |

| Pressure Drop | Lowest pressure drop | Highest pressure drop | Moderate pressure drop |

| Pressure Capability | Ideal for low pressure systems | Ideal for high pressure systems | Ideal for both low and high pressure systems |

| Temperature Capability | Works well with high temperatures | Work well with high temperatures | Works well with high temperatures |

| Flow Velocity Capability | Does not work well with high flow velocity | Works well with high flow velocity | Works well with high flow velocity |

| Pulsating and Changing Flow Capability | Does not work well pulsating flow or frequently changing flow conditions | Works well with pulsating flow or frequently changing flow conditions | Does not work well with pulsating flow or frequently changing flow conditions |

| Wear Over Time | Most susceptible to premature wear from disc oscillating or slamming | Least susceptible to premature wear from disc oscillating and slamming | Moderately susceptible to premature wear from disc oscillating and slamming |

| Service Life and Maintenance | Shortest service life and low maintenance needs | Longest service life and low maintenance needs | Moderate service life and higher maintenance needs |

| Overall Cost | Lowest cost | Highest cost | Mid-level cost |

| Suitable Applications | Performs well in water supply, water treatment, boiler systems, HAVC, plumbing, irrigation, and industrial processing systems like power and chemical plants and gas transmission and refineries | Performs well in pumping stations, boilers, HVAC, irrigation, fire protection systems, and marine applications as well as the high rise buildings of industrial applications like water supply, water treatment, power plants, and chemical processing | Performs well in heat recovery steam, steam generation, boiler circulation, boiler feed water, power plants, safety systems, geothermal service, shutdown cooling, turbine cooling, utilities, and hydrocarbon processing |

Swing, Lift, and Stop Check Valves all clearly have many unique features that determine what applications and working conditions they will perform best in, each type having their own advantages and disadvantages. Understanding how the different check valves work will help guide you as you make the best possible choice for your operations, whether you're looking for a valve that will support an unobstructed, low-velocity flow with low press drop or a valve that lasts through harsh working and flow conditions with minimal wear or a valve with the versatility of combined check and globe valve functions and both high and low pressure capabilities. Now that you've read up on everything check valve, we're confident in your ability to pick the right check valve for you and Cooney Brothers has the complete product selection to supply exactly what you need.

Explore our full range of Swing Check Valves, Lift Check Valves, and Stop Check Valves from the popular brands you know and love like Aloyco, Apollo, Crane, Spears, and more.

Contact us for the products and technical expertise that you need to get your job done, and fast!