Gate Valves vs Globe Valves

How to Differentiate Between Gate Valves and Globe Valves for Your Best Application

A debate as old as time; gate valves or globe valves?

Both valves act as important players in countless industrial, commercial, and residential applications.

Whether you’re designing a new piping system or looking to replace a worn-out valve, picking the right product for your unique needs must be top priority. While gate and globe valves look very similar in design and can be used in the same systems, this is where their similarities end. Each valve has a distinct set of functions, components, and features that set themselves apart from one another. Neither is necessarily "better" than the other; they simply serve different purposes and often perform better in different applications and working conditions.

Let start growing your understanding by defining each valve and their characteristics:

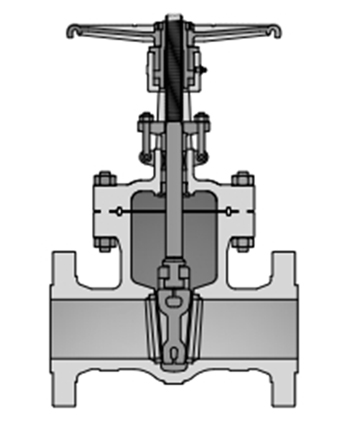

What are Gate Valves?

Gate Valves are shut-off valves that support full on and full off services using flat or wedge-shaped discs. These discs are activated by the turning of a handwheel that rotates the connected stem to move the disc fully up or fully down. The disc operates like a gate by lifting away from its seat for open flow and lowering back onto the seat for complete flow shut off, hence the “gate” name.

With the choice of rising or non-rising stems for small space applications, Gate valves have a simple structure where components are located at the upper part of a hollow valve body. While this structure does leave the stem possibly exposed to flow and corrosive conditions, it can be easily accessed for installation or repair, and it promotes a low amount of pressure drop. These valves have linear, straight-through flow paths that can move freely in either direction with very little flow resistance. This makes gate valves ideal for applications that require top flow efficiency when opened and a tight seal when closed, where pressure levels must remain consistent. The full shut off capability is particularly advantageous for maintenance and repairs as it enables sections of a pipeline to be completely isolated from flow. While gate valves can be more susceptible to wear over time, they are still able to withstand moderately high levels of heat, high levels of pressure, and corrosive or abrasive media.

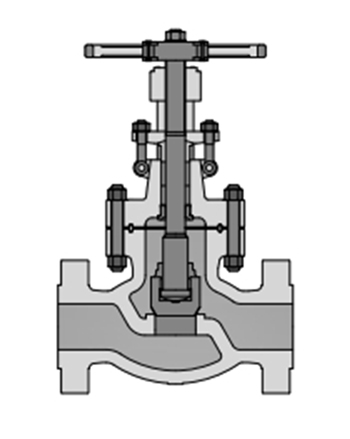

What are Globe Valves?

Globe Valves are control valves that can be both fully and partially opened or closed for precise flow control using spherical, plug-like discs. These discs are also activated by the turning of a handwheel and stem that moves the disc fully up or down as well as into partial positions that sit anywhere in between. Exact flow rate is regulated by how far the disc is lifted towards or away from its seat ring, ensuring start, stop, and regulate flow capabilities.

Typically only available with rising stems, globe valves have a more complex structure where components are housed more internally within a valve body that is completely solid all the way through. While this structure makes accessing these components more difficult for installation, maintenance, and repair, it also allows the stem to be free from flow exposure and therefore, free from corrosive damages. Globe valves only flow in one direction using a curved, typically nonlinear flow path since the internal design, especially when throttled, requires fluid to slightly change the angle of flow direction, in turn causing some flow resistance and possible high drop/changes in pressure. This makes globe valves ideal for applications that require frequent throttling services or general flow adjustments, where pressure changes and slight resistance in flow are not a concern. Globe valves’ fully solid and highly durable construction also make them better suited for applications that use extreme high temperatures, varying levels of pressure, and corrosive or abrasive media.

Quite a bit of information to keep track of right? See the table below for a quicker, easier way to compare globe valves vs gate valves and for even more contrasting characteristics:

Differentiating Between Gate Vaves and Globe Valves

|

|

Gate Valves | Globe Valves |

|---|---|---|

| Function | Full on and full off services | Precise flow control with full on and full off capabilities |

| Valve Body | Rectangular shape, internally hollow when open | Spherical shape, internally solid all the way through except for flow channel |

| Disc | Gate-like disc in flat or wedge shape | Plug-like disc in spherical shape |

| Flow Path | Linear, straight-through flow | Typically nonlinear, curved flow (while uncommon, can be specially made with more linear designs) |

| Flow Direction | Bidirectional | Unidirectional (intended direction usually indicated on valve body using an arrow) |

| Flow Efficiency | Little to no flow resistance when open | some flow resistance, especially when throttling |

| Pressure Capability | Minimal pressure drop ensures valve is better equipped to handle high pressure levels | High pressure drop makes valve less equipped to maintain high pressure levels but better equipped to handle varying pressure levels |

| Maximum Temperatures | Lower maximum operating temperature | Higher maximum operating temperature |

| Durability | Thinner walls and hollow body leave valve more susceptible to moving out of alignment and corrosion exposure, causing leaks | Thicker walls and solid, robust construction make valve less susceptible to corrosive damage and leakage |

| Service Life | Shorter service life due to possible wear over time | Longer service life due to minimal wear over time |

| Installation & Maintenance | Simple, easy to reach components ensures an easier and quicker installation and maintenance | Complex, internal components are hard to reach, making installation and maintenance a harder, longer process |

| Overall Cost | Cheaper valve itself and cheaper installation/maintenance with higher long-term repair costs | More expensive valve itself and more expensive installation/maintenance with lower long-term repair costs |

| Application Type | Applications that require uninterrupted, straight-through flow and/or the ability to isolate sections of a pipeline | Applications that require throttling services and precise flow control down to exact flow rate |

| Best Paired Applications | General water supply, plumbing systems, HVAC systems, oil and gas pipelines, steam lines, agriculture, irrigation, marine industries, mining industries, and many types of process plants including power generation, water and wastewater treatment, chemical industries, and food and beverage industries | Small water supply systems, plumbing systems, HVAC systems, coolant water systems, sprinkler systems, chemical feed systems, oil and gas pipelines, steam lines, boiler lines, and many types of process plants including power generation, water and wastewater treatment, chemical industries, food and beverage industries, and drainage systems |

As you can see, gate and globe valves each have their own advantages and disadvantages. Now that you are familiar with these features, you can make a fully informed decision on which valve would be the most effective and efficient choice for your particular system. No matter how unique the need, Cooney Brothers has the full product selection and industry-specific experience to effectively support your business.

Explore our extensive supply of Gate Valves and Globe Valves from the top-picked brands you know and love such as Aloyco, Apollo, Crane, Spears, and more!

Contact us for the technical advice and expertise you need to make the best possible choice your specific application. Backed by 85 years of industry experience, we will help you get the job done so you can focus on your business, and we'll handle the rest.