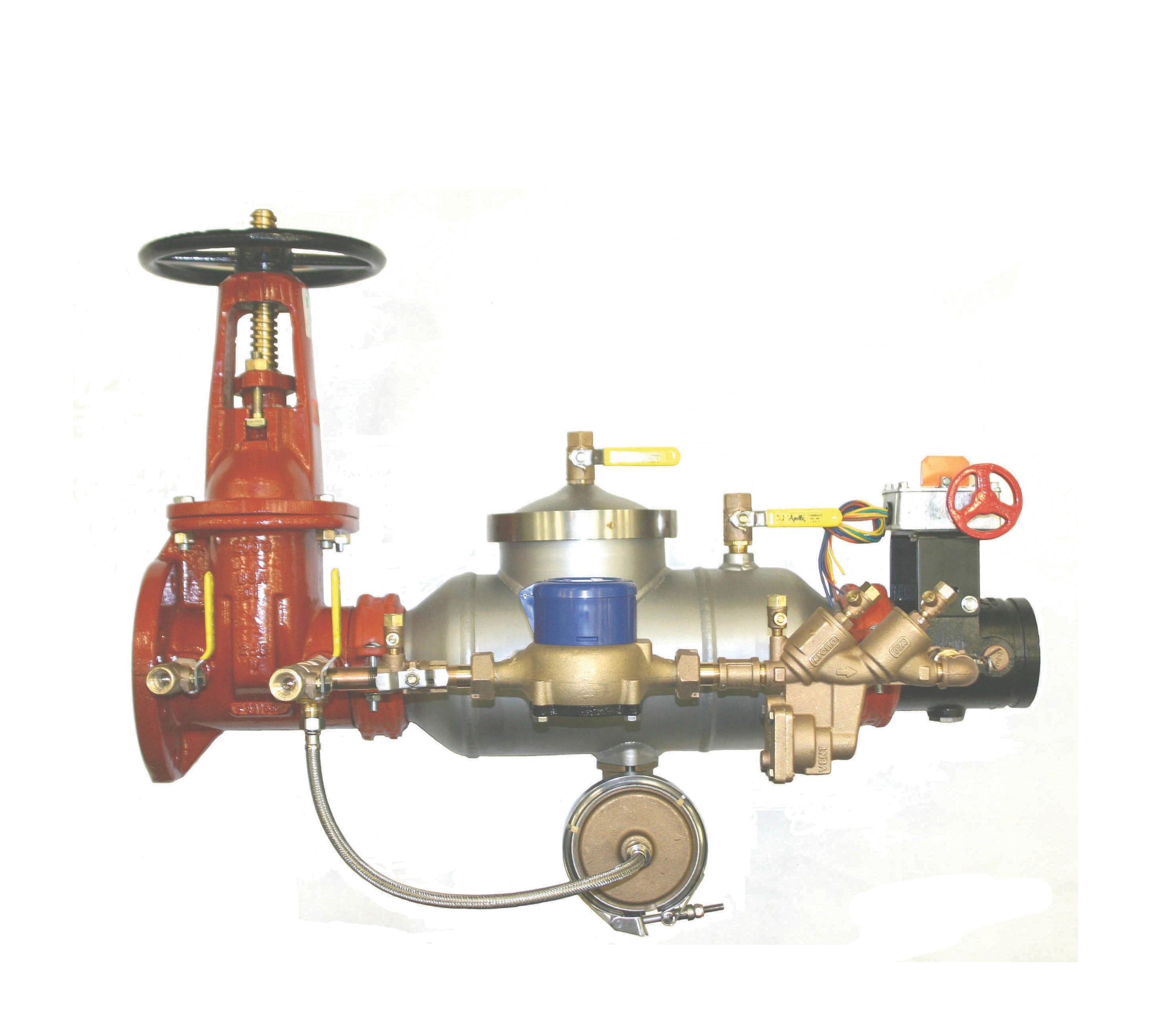

Apollo™ 4ALF70AG9 RPDALF4A Type 1 Backflow Preventer, 4 in Nominal, Monitored Butterfly Valve Groove End Style, 304 Stainless Steel Body, Reduced Pressure, Domestic

CBPN:247337

UPC:670750578830

MPN:4ALF70AG9

DESCRIPTION

Apollo™ 4ALF70AG9, Backflow Preventer, Type 1, Series: RPDALF4A, 4 in Nominal, Monitored Butterfly Valve Groove End Style, 175 psi Pressure, 33 to 140 deg F, Reduced Pressure Backflow, Media: Water, 304 Stainless Steel Body, Domestic

The 2-1/2 in to 12 in Reduced Pressure Detector Assembly shall be an Apollo™ Model RPDALF4A or RPDA2LF4A. The assembly shall be manufactured in America and carry a 5-year Apollo™ factory warranty. The TriForce™ center-stem guided check valves shall feature reversible silicone rubber seat discs. The check valves shall be held in place by stainless steel snap-in retainers (2-1/2 in to 6 in) or stainless steel studs & nuts (8 in to 12 in). Access to the check valves and relief valve internals shall be by an Apollo™ quick-connect stainless steel coupling (2-1/2 in to 6 in) or grooved couplings (covers) and stainless steel bolts (relief valves) (8 in to 12 in). The bodies shall be stainless steel in 2-1/2 in to 8 in sizes and FDA epoxy-coated ductile iron in 10 in & 12 in sizes. The assembly is a mainline RP with a Type 2 bypass consisting of a lead free single check valve (SCV) and meter bypassing the mainline second check to prevent backflow while accurately measuring all flows up to 2 gpm with the mainline 2nd check remaining closed. Assemblies with the optional Type 1 bypass consist of a lead free RP and meter which bypasses both mainline checks and accurately meters all flows up to 2 gpm with both mainline checks closed. The Apollo™ domestic ball valve test cocks shall have stainless steel handles. Both Reduced Pressure relief valves shall be positioned at the bottom of their respective assemblies with separate center-access covers. The pressure drop across the assembly shall be documented by an independent laboratory. The assembly shall prevent contamination of the potable water supply due to back-siphonage or back pressure from substances that are health or non-health hazards.

Apollo™ 4ALF70AG9 RPDALF4A Type 1 Backflow Preventer, 4 in Nominal, Monitored Butterfly Valve Groove End Style, 304 Stainless Steel Body, Reduced Pressure, Domestic

CBPN:247337

MPN:4ALF70AG9

UPC:670750578830

DESCRIPTION

Apollo™ 4ALF70AG9, Backflow Preventer, Type 1, Series: RPDALF4A, 4 in Nominal, Monitored Butterfly Valve Groove End Style, 175 psi Pressure, 33 to 140 deg F, Reduced Pressure Backflow, Media: Water, 304 Stainless Steel Body, Domestic

The 2-1/2 in to 12 in Reduced Pressure Detector Assembly shall be an Apollo™ Model RPDALF4A or RPDA2LF4A. The assembly shall be manufactured in America and carry a 5-year Apollo™ factory warranty. The TriForce™ center-stem guided check valves shall feature reversible silicone rubber seat discs. The check valves shall be held in place by stainless steel snap-in retainers (2-1/2 in to 6 in) or stainless steel studs & nuts (8 in to 12 in). Access to the check valves and relief valve internals shall be by an Apollo™ quick-connect stainless steel coupling (2-1/2 in to 6 in) or grooved couplings (covers) and stainless steel bolts (relief valves) (8 in to 12 in). The bodies shall be stainless steel in 2-1/2 in to 8 in sizes and FDA epoxy-coated ductile iron in 10 in & 12 in sizes. The assembly is a mainline RP with a Type 2 bypass consisting of a lead free single check valve (SCV) and meter bypassing the mainline second check to prevent backflow while accurately measuring all flows up to 2 gpm with the mainline 2nd check remaining closed. Assemblies with the optional Type 1 bypass consist of a lead free RP and meter which bypasses both mainline checks and accurately meters all flows up to 2 gpm with both mainline checks closed. The Apollo™ domestic ball valve test cocks shall have stainless steel handles. Both Reduced Pressure relief valves shall be positioned at the bottom of their respective assemblies with separate center-access covers. The pressure drop across the assembly shall be documented by an independent laboratory. The assembly shall prevent contamination of the potable water supply due to back-siphonage or back pressure from substances that are health or non-health hazards.

Specifications

Item Features

- Easy maintenance no special tools required

- Low pressure loss as documented by an independent laboratory

- Center-stem guided TriForce check valves

- Modular captured spring relief valve

- Snap-in check retainers

- Less meter