Apollo™ 4ALF20909 RPLF4A Standard Principle Backflow Preventer, 2-1/2 in Nominal, Monitored Butterfly Valve Groove End Style, Bronze Body, Reduced Pressure, Domestic

CBPN:247079

UPC:670750669729

MPN:4ALF20909

DESCRIPTION

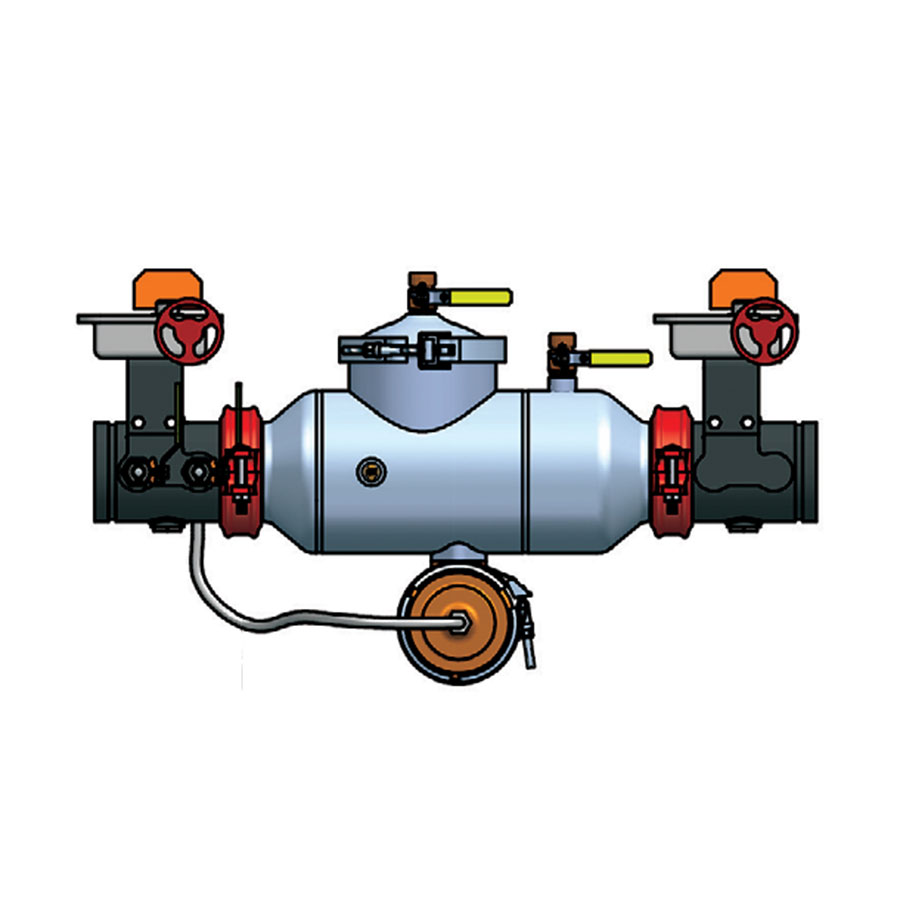

Apollo™ 4ALF20909, Principle Backflow Preventer, Standard, Series: RPLF4A, 2-1/2 in Nominal, Monitored Butterfly Valve Groove End Style, 175 psi Pressure, 33 to 180 deg F, Reduced Pressure Backflow, Full Port, Bronze Body, Domestic

The Apollo™ Model RPLF 4A Reduced Pressure Principle Backflow Preventers consist of two independently acting, TriForce™ center stem guided check valves with a differential pressure relief valve located between the check valves. The unit is designed to give maximum protection against backflow of health or non-health hazard fluids by either back-pressure or back-siphonage. The durable domestic stainless steel units (2-1/2 in - 8 in) and the FDA epoxy coated ductile iron units (10 in and 12 in) are easily maintained in the line without any special tools. The TriForce™ check valves operate with a spring assist in the flowing condition to provide excellent flow rates which are documented by an independent laboratory.

Apollo™ 4ALF20909 RPLF4A Standard Principle Backflow Preventer, 2-1/2 in Nominal, Monitored Butterfly Valve Groove End Style, Bronze Body, Reduced Pressure, Domestic

CBPN:247079

MPN:4ALF20909

UPC:670750669729

DESCRIPTION

Apollo™ 4ALF20909, Principle Backflow Preventer, Standard, Series: RPLF4A, 2-1/2 in Nominal, Monitored Butterfly Valve Groove End Style, 175 psi Pressure, 33 to 180 deg F, Reduced Pressure Backflow, Full Port, Bronze Body, Domestic

The Apollo™ Model RPLF 4A Reduced Pressure Principle Backflow Preventers consist of two independently acting, TriForce™ center stem guided check valves with a differential pressure relief valve located between the check valves. The unit is designed to give maximum protection against backflow of health or non-health hazard fluids by either back-pressure or back-siphonage. The durable domestic stainless steel units (2-1/2 in - 8 in) and the FDA epoxy coated ductile iron units (10 in and 12 in) are easily maintained in the line without any special tools. The TriForce™ check valves operate with a spring assist in the flowing condition to provide excellent flow rates which are documented by an independent laboratory.

Specifications

Item Features

- Easy maintenance no special tools required

- Low pressure loss as documented by an independent laboratory

- Center-stem guided TriForce check valves

- Approved for horizontal flow

- Snap-in check retainers